Exactly how to Choose the Best Heat Transfer Fluid for Industrial Applications

Exactly how to Choose the Best Heat Transfer Fluid for Industrial Applications

Blog Article

Why Heat Transfer Fluid Is Necessary for Optimizing Power Transfer in Systems

The role of warmth transfer fluids in optimizing energy transfer is essential for achieving efficient thermal management across various commercial industries. These liquids facilitate smooth warmth exchange, making sure processes operate within ideal temperature varieties and mitigating the danger of getting too hot.

Function in Thermal Management

Heat transfer fluids play an important role in thermal management by efficiently controling temperatures in numerous industrial processes and systems. These specialized liquids facilitate the transfer of heat in between various components, making sure ideal operating conditions and protecting against getting too hot. By keeping accurate temperature control, warmth transfer fluids allow markets such as chemical manufacturing, oil and gas, and power generation to run securely and efficiently.

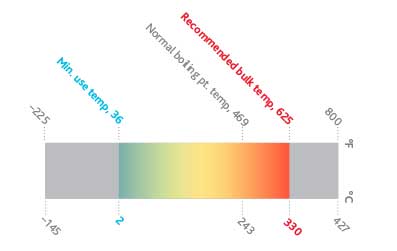

The selection of an appropriate heat transfer fluid depends upon several factors, including thermal stability, heat capability, and viscosity. High thermal stability guarantees that the liquid can endure extreme temperatures without degrading, while a high warm capability enables it to take in and release considerable amounts of warm - heat transfer fluid. Reduced thickness reduces the energy needed for pumping, adding to general system effectiveness

Furthermore, warmth transfer liquids are important in applications like refrigeration, where they help absorb and dissipate heat throughout the cooling cycle. In solar thermal power systems, these fluids capture and transportation solar heat to produce electrical energy or supply warm water. Their versatility to varied operating conditions and capacity to keep constant thermal efficiency highlight their relevance in industrial thermal administration, facilitating functional continuity and enhancing precaution.

Enhancing System Efficiency

To maximize the advantages of thermal management, improving system effectiveness via the calculated usage of warm transfer fluids is paramount. By preserving ideal temperature levels, heat transfer liquids aid make sure that systems run within their designed specifications, consequently avoiding overheating and reducing the danger of part failure.

Kinds Of Heat Transfer Liquids

The diversity of warm transfer fluids underscores their essential role in an array of commercial applications, each customized to satisfy certain thermal monitoring demands. These fluids promote effective power transfer and are chosen based upon essential residential or commercial properties such as thermal stability, viscosity, and heat capacity. The key kinds include water, glycol services, oils, and synthetics, each offering unique benefits.

Water is the most usual warm transfer medium due to its high specific warm ability and inexpensive. Its usage is restricted by its freezing and boiling factors. Glycol combinations, often utilized in cooling and heating systems, offer a lower freezing point, including flexibility in different climates. Mineral oils are preferred for their thermal stability and non-corrosive nature, making them ideal for high-temperature applications.

Synthetic fluids, including silicone and fragrant substances, offer remarkable thermal security and are used in settings demanding extreme temperature level arrays. These liquids guarantee remarkable performance in systems where traditional fluids might stop working. The selection of a warmth transfer fluid is vital, as it affects system effectiveness, security, and longevity. Each kind needs to be chosen to align with page the functional needs and the details problems of the application it serves.

Environmental and Economic Benefits

Using the appropriate warmth transfer fluids supplies substantial ecological and financial benefits for industrial procedures. Ecologically friendly heat transfer liquids, usually naturally degradable and non-toxic, minimize the danger of soil and water contamination in the occasion of leaks or spills, thereby securing ecosystems and abiding with rigorous ecological regulations.

Financially, the best warmth transfer liquid can substantially lower functional costs. Fluids with extensive lifecycle performance decrease the frequency of substitutes and upkeep, lowering downtime and associated costs. On the whole, the tactical usage of optimum warm transfer liquids supports lasting financial growth and environmental stewardship.

Picking the Right Liquid

How does one navigate the complicated process of choosing the ideal heat transfer liquid for commercial applications? Thermal stability guarantees the liquid can hold up against high temperatures without deteriorating, while compatibility prevents rust or other harmful reactions with system elements.

In addition, the fluid's warm ability and thickness are paramount. A high heat capability enables the fluid to take in and transfer websites more power, boosting performance.

Final Thought

The strategic choice and application of heat transfer fluids are fundamental to optimizing power transfer across numerous systems. By making sure high thermal stability and capability, these liquids provide precise temperature control and enhance total system performance.

Report this page